SPOILER ALERT!

Tunnel Pasteurizers Are Highly-Effective Pasteurization Remedies For Foods As Well As Drinks

Content by-Nymann Overby

They are ergonomic and sustainable, and they use an unique control software to maximize efficiency and lower water usage. This ensures a high degree of hygienic efficiency. Learn Additional offers simple ease of access to the components, enabling very easy cleansing and replacement of inlet displays. Tunnel Pasteurizers can likewise be used in combination with warm filling up methods, consisting of warm filling modern technology.

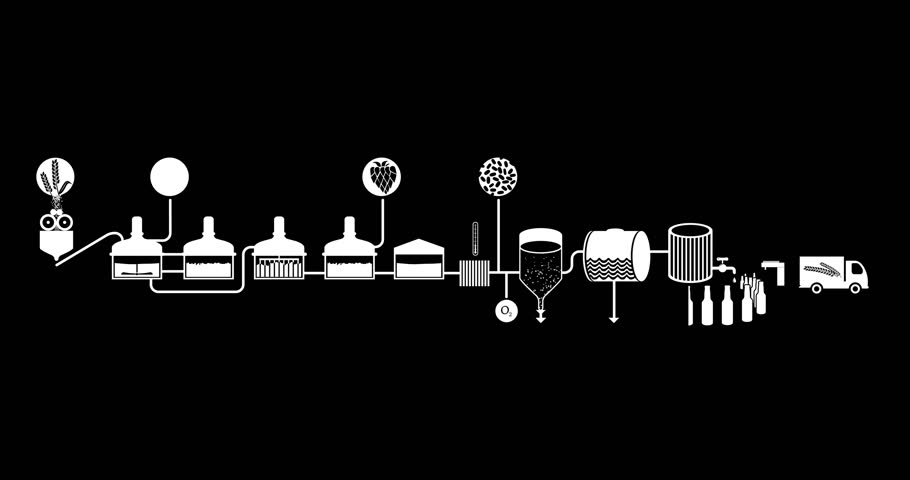

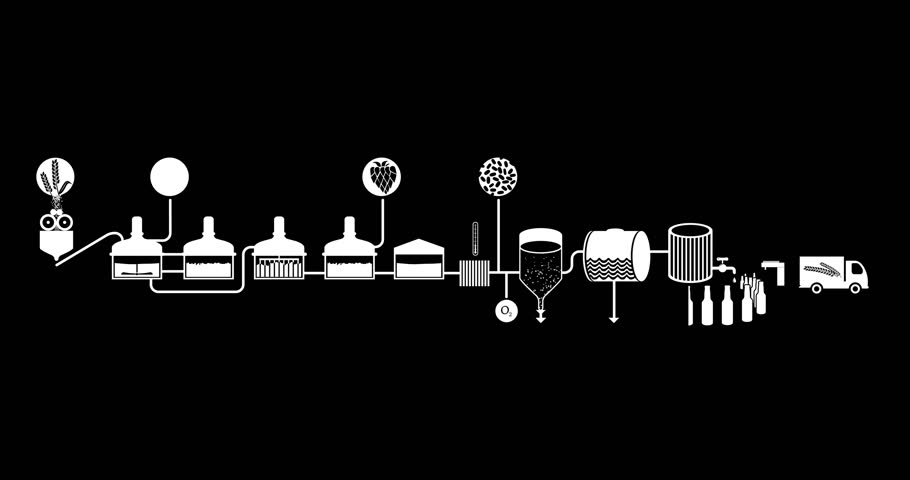

The Tunnel pasteurizer procedure removes recurring microorganisms from food as well as beverages. They are effective and also be available in various sizes to match different demands. They are used in the food and drink industries to eliminate microorganisms, quit fermentation, and offer shelf stability. Nonetheless, they undergo high mechanical anxiety and also temperature level variations, and also busted bottles can create damages to the equipment. PRO Engineering/Manufacturing has been offering the sector with high quality Tunnel pasteurizers for years as well as has actually constructed numerous types as well as sizes.

Tunnel pasteurization is useful for carbonated beverages, which may have a lengthy life span in between manufacturing and usage. Some beverages sit on racks for weeks before being consumed. They can also take a trip fars away, investing a period in a cupboard or refrigerator after purchase. For this reason, Tunnel pasteurization helps maintain quality and also flavor of these beverages. The process is also valuable for delicate packaging, consisting of glass as well as aluminum containers. The sudden change in temperature can bring about the rupture of these containers, that makes it essential to use the essential precautions.

Tunnel Pasteurizers can be made use of to sterilize beverages without chemicals. They use a warm resource, enhancing the number of temperature level areas as well as minimizing microbes. The temperature level is increased up until the called for pasteurization temperature level is accomplished. Once the pasteurization process is complete, the drink is cooled down to avoid any kind of prospective damages.

Tunnel Pasteurizers are not just made use of in beverage production, however additionally in the beer market. Its warmth exchange attribute helps recoup power through various temperature areas. Its enhanced nozzle system makes certain great heat exchange with the item. Additionally, Tunnel pasteurizers feature water-saving functions. They gather the water collected during the pasteurization process, while likewise preserving high hygienic requirements.

Tunnel Pasteurizers are an excellent selection for large production processes. These systems are an economical, easy-to-use choice to sterilized purification and also flash pasteurization. They can likewise prevent wear and tear of taste. Some models feature automated quit systems to prevent overpasteurization. They also can be found in different sizes as well as measurements. They can be tailored to meet specific client needs.

Temperature sensors are a crucial function of pasteurization units. They are used to determine the pasteurization worths. These dimensions are done utilizing a formula that computes the PUs. Tunnel Pasteurizers have the ability to check the water temperature with high accuracy. Additionally, they are developed for long-term usage. For the best outcomes, temperature sensing units must be placed at critical points. Additionally, calibration systems need to tape-record temperature level and also stress within the process shipment system.

A tunnel pasteurizer can be used for large-scale productions that have high filler prices. In these cases, a tunnel pasteurizer is needed to avoid germ exposure to the downstream tools. Using this innovation will certainly allow assembly line to maintain the finest quality standards as well as eliminate risk of contamination.

They are ergonomic and sustainable, and they use an unique control software to maximize efficiency and lower water usage. This ensures a high degree of hygienic efficiency. Learn Additional offers simple ease of access to the components, enabling very easy cleansing and replacement of inlet displays. Tunnel Pasteurizers can likewise be used in combination with warm filling up methods, consisting of warm filling modern technology.

The Tunnel pasteurizer procedure removes recurring microorganisms from food as well as beverages. They are effective and also be available in various sizes to match different demands. They are used in the food and drink industries to eliminate microorganisms, quit fermentation, and offer shelf stability. Nonetheless, they undergo high mechanical anxiety and also temperature level variations, and also busted bottles can create damages to the equipment. PRO Engineering/Manufacturing has been offering the sector with high quality Tunnel pasteurizers for years as well as has actually constructed numerous types as well as sizes.

Tunnel pasteurization is useful for carbonated beverages, which may have a lengthy life span in between manufacturing and usage. Some beverages sit on racks for weeks before being consumed. They can also take a trip fars away, investing a period in a cupboard or refrigerator after purchase. For this reason, Tunnel pasteurization helps maintain quality and also flavor of these beverages. The process is also valuable for delicate packaging, consisting of glass as well as aluminum containers. The sudden change in temperature can bring about the rupture of these containers, that makes it essential to use the essential precautions.

Tunnel Pasteurizers can be made use of to sterilize beverages without chemicals. They use a warm resource, enhancing the number of temperature level areas as well as minimizing microbes. The temperature level is increased up until the called for pasteurization temperature level is accomplished. Once the pasteurization process is complete, the drink is cooled down to avoid any kind of prospective damages.

Tunnel Pasteurizers are not just made use of in beverage production, however additionally in the beer market. Its warmth exchange attribute helps recoup power through various temperature areas. Its enhanced nozzle system makes certain great heat exchange with the item. Additionally, Tunnel pasteurizers feature water-saving functions. They gather the water collected during the pasteurization process, while likewise preserving high hygienic requirements.

Tunnel Pasteurizers are an excellent selection for large production processes. These systems are an economical, easy-to-use choice to sterilized purification and also flash pasteurization. They can likewise prevent wear and tear of taste. Some models feature automated quit systems to prevent overpasteurization. They also can be found in different sizes as well as measurements. They can be tailored to meet specific client needs.

Temperature sensors are a crucial function of pasteurization units. They are used to determine the pasteurization worths. These dimensions are done utilizing a formula that computes the PUs. Tunnel Pasteurizers have the ability to check the water temperature with high accuracy. Additionally, they are developed for long-term usage. For the best outcomes, temperature sensing units must be placed at critical points. Additionally, calibration systems need to tape-record temperature level and also stress within the process shipment system.

A tunnel pasteurizer can be used for large-scale productions that have high filler prices. In these cases, a tunnel pasteurizer is needed to avoid germ exposure to the downstream tools. Using this innovation will certainly allow assembly line to maintain the finest quality standards as well as eliminate risk of contamination.